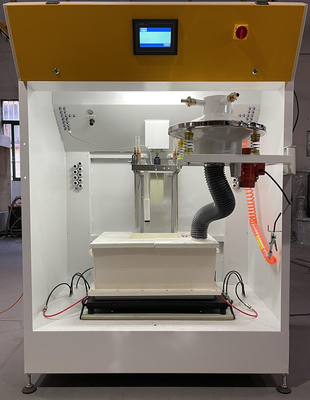

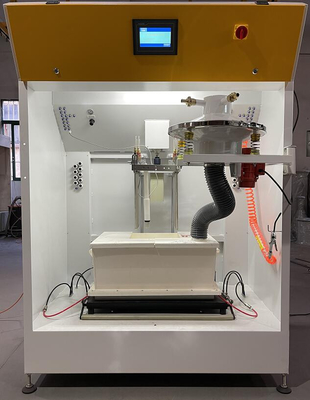

High Effeciency Powder Feed Center For Automatic Powder Coating Line

Product introduction

The powder supply center can supply powder in two ways:

1. Directly supply powder from the powder box of the powder supplier - when the amount of powder used is small, in order to avoid pouring into and out of the powder hopper.

2. The powder is supplied from the engineering plastic powder bucket with fluidization system. When the powder suction pipe of the powder supply center is directly sucked from the original powder box of the powder manufacturer. When the powder is taken and transported, the combination of local fluidization and vibration allows the powder transport to always maintain an optimal state. When the engineering plastic powder bucket with fluidization function is used, the insertion depth of the powder emitter is controlled by the powder level sensor. The recovered powder is screened by the vibrating screen, the dirt or large particles caused by cleaning are separated, and the clean powder is collected into the powder supply center.

Product features

The main features of the powder supply center are:

-Handle the powder supplied by the original powder box or the new powder unit.

-It has its own recovery device.

-Integrated electrical control.

-The powder level is monitored by the powder level detector.

-The powder level detector controls the rise and fall of the powder conveying device, which is equipped with all venturi powder pump and fluidizing gas pipe.

-The inside of powder suction pipe, powder pump, powder pipe and spray gun can be cleaned automatically.

-The recovered powder is directly sent to the powder supply box.

-It has a recovery system to prevent powder overflow during spraying production and color change.

Wide application

The powder supply center is specially designed for fast color change, replacing the traditional powder supply hopper. Place the powder box provided by the powder supplier.

At the position of fluidized powder bucket. The powder box can be returned to the warehouse after use.

The powder supply center is an integrated part of the rapid color change system, which affects the spraying quality of the final product. Usually

As the core part of automatic production.

Product advantage

1. Fast color clearance.

2. Self clearance function.

3. Large supply of powder

4. Clean and high effeciency.

Quick Details

|

Product

|

Powder center |

Voltage |

380V |

| Application |

Powder coating line |

Power |

3Kw |

| Advantage |

Fast color changing |

Air pressure |

0.6 - 0.8 Kpa |

| Capacity |

Support 30 automatic spray guns together |

Selling point |

Automatically self - cleaning function |

| Place of Origin |

Cangzhou,China |

Warranty |

1 year |

Package

Wooden box package

Company introduction

Astar Machinery Co., Ltd. is a comprehensive service in production, R&D; and sales, operates mainly in electrostatic spraying equipment, including electrostatic dust elimination equipment; electrostatic flocking machine, electrostatic powder spraying machine, electrostatic liquid spray machine, electrostatic spraying gun, high voltage module, circuit board, powder barrel, powder tube, Hv cable, reciprocator, spraying room, control cabinet, oven, oven, vibration sieve, the wind leaching room, supply Gema, KCI, Wagner accessories, professional wholesale gun shell, venturi tube, powder pump, deflector, nozzle, electrode holder and other products.

Picture

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!